Sun Fast provides offshore sourcing for custom metal castings.

Casting parts

International Sourcing for Custom Metal Castings

The offshore manufacturing and processing of custom metal castings provides a wide range of advantages that are more difficult to achieve through nearshore manufacturing. Offshore sourcing for investment casting, die casting, and sand casting allows for less expensive labor, easier acquisition of skilled laborers, and increased access to less expensive raw materials.

Sun Fast provides offshore services for custom metal castings. We offer strategic sourcing for sand casting, precision casting, and die casting methods. No matter what casting method your project requires, our offshore partners consistently deliver high-quality cast metal products that meet or exceed expectations. With our proven offshore manufacturing process, we’ll work with you from sourcing the manufacturer to prototype to production.

Contact us for more information regarding our offshore sourcing for custom metal castings or call us at 714-680-8288 and we will gladly answer any questions that you may have. Sun Fast is your trusted source for precision metal casting offshore sourcing capabilities.

Can't Find What You're Looking For?

We're dedicated to helping and providing our customers with quality, custom metal and plastic components and fully assembled products.

Custom Sand Casting

Custom Sand casting can be used to produce a wide range of components, including large, heavy, and/or complex parts. Whether your project requires aluminum sand casting, stainless steel sand casting, steel sand casting, or iron sand casting methods, Sun Fast has an offshoring partner that will meet your needs.

Advantages of Stainless Steel Sand Casting and Other Metals

Sand casting is a very popular method of casting for varied reasons, some of which include:

- Low cost

- Ability to cast very large parts

- Both ferrous & non-ferrous metals can be cast

- Low post-casting tooling cost

Custom Investment Casting

Investment casting, also known as precision casting, allows for more intricate and complex forms than other casting methods and can be used to produce parts that would be difficult or impossible to create through other processes. At Sun Fast, we provide aluminum investment casting, stainless steel investment casting, steel investment casting, or iron investment casting offshoring options to meet your specification requirements.

Advantages of Stainless Steel Investment Casting and Other Metals

Offshore sourcing for investment casting offers many distinct advantages over other casting methods, some of which include:

- Parts created in a wide range of materials from steel to stainless steel

- High dimensional accuracy

- Excellent surface finish

- Able to cast extremely intricate parts

- No flash or parting lines

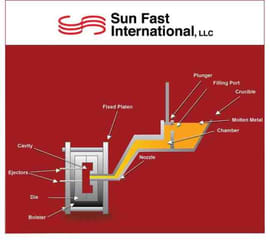

Custom Die Casting

Die casting is an ideal process for creating smaller pieces and more intricate part designs. Molds for die casting are created from hardened tool steel which is machined into the desired shape. Sun Fast’s offshore sourcing capabilities include aluminum die casting, stainless steel die casting, steel die casting, and iron die casting processes.

Advantages of Customized Die Casting

Die casting is an effective, cost-effective process offering a larger range of shapes and components than any other manufacturing technique. Engineers can gain many advantages by specifying die cast parts, some of the benefits of die casting include:

- Parts created in a wide range of materials from zinc to aluminum

- Strength & weight

- Multiple finishing techniques

- High-speed production

- Dimensional accuracy & stability

- Simplified assembly

Why Choose Sun Fast for Outsourced Metal Casting?

Sun Fast offers complete, turnkey offshore sourcing for your metal casting project needs. This includes the manufacturing process of the raw casting material, additional precision machining services, plating, powder coating, and E-coating services. Working from your designs, we will deliver custom metal castings that meet or exceed your expectations.

Contact Sun Fast for International Sourcing of Your Metal Castings

Contact us for more information regarding our custom metal casting offshore options including sand casting, investment casting, and die casting methods. Our vetted manufacturers in southeast Asia include Taiwan and Vietnam. Submit a project for further pricing details today. Sun Fast International is your premier resource for offshoring of metal casting production.