Off Shore Sourcing for Cold Heading Forging & Manufacturing

|

| Forging parts |

Cold heading fabrication is the process of reshaping metal wire into a desired shape for the purposes of making a functioning fastener product. Offshoring cold heading produces advanced quality large and small diameter cold headed parts and components for the automotive, agriculture and consumer electronics industries.

Sun Fast provides strategic sourcing for the cold head fabrication of metal parts and components. Our cold heading partners can deliver high quality, custom metal products manufactured to your design specifications.

Contact us for more information regarding our off shore sourcing for cold heading forging partners, or call us at 714-680-8288 and we will answer your specific cold heading fabrication questions. At Sun Fast, we can connect you with an offshore cold heading manufacturer that will work with you to deliver the cold headed parts and components that are based on your company’s exact design specifications.

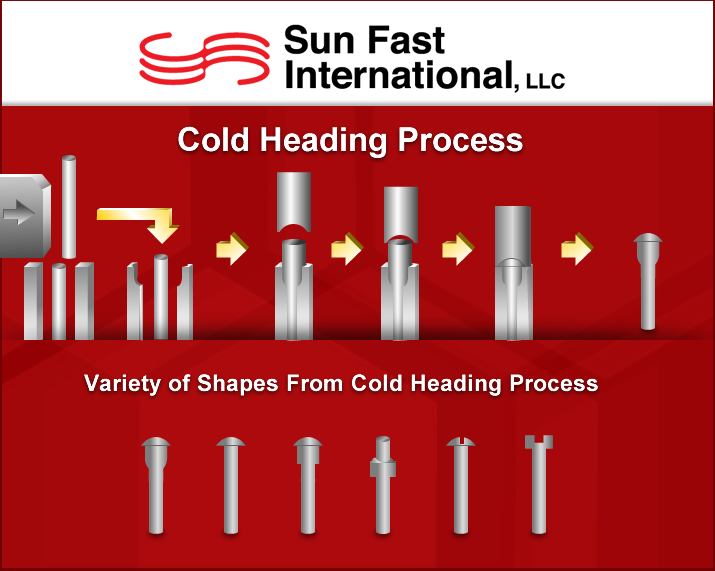

The Steel Cold Heading Process

Cold heading is a metalworking process that utilizes high speed, automated equipment to form metal (usually in the form of wire or strip) into finished parts. Complex parts with tight tolerances can be created quickly and cost-effectively through the cold head fabrication process. Additionally, cold headed forgings can be repeated with near-perfect precision in quantities in the tens of thousands. The steel cold heading process is comprised of various stages provides work hardening of the base metal. The cold headed stages include:

- Spool Insertion

- Progressive Die Engineering

- Part Production

The results of the steel cold heading manufacturing process are finished parts that are stronger than the original material from which they’re made.

Offshore Cold Heading Industrial Applications

Sun Fast’s cold heading partners can produce parts in a wide variety of sizes. This including those with numerous metal makeups, and those with custom configurations to meet the needs of almost any application. Due to these options, we serve clients in a broad spectrum of industries including:

- Medical & Dental – We provide extremely small cold headed metal parts made from, or plated with, biocompatible materials for dental implants and medical devices.

- Automotive – Sun Fast also provides cold headed forgings for the automotive industry that are made from carbon steel or other high strength materials.

- Electronic Devices – Cold head fabrication is also used to produce solid and bimetal contact rivets for electronic devices.

The unique, “custom” nature of the cold heading process allows for almost unlimited possibilities in part design.

Why Choose Offshore Cold Heading Fabrication?

There is a substantial investment cost associated with purchasing and housing the machines that produce cold headed steel parts and components. In addition, professional employee labor costs to operate the machines that produce cold-headed products can be extremely high. Other considerations include the additional square footage housing costs associated with storing the machines, as well as machine upkeep and repairs.

Off Shore Cold Heading Fabrication Benefits

The cold heading process produces parts and components that are completely customized to your exact specification requirements. This can include customized head shapes, multiple upset configurations, and substitutions for multi-part assemblies. Some of the advantages of working with a trusted offshore sourcing agent like Sun Fast for your offshoring cold heading manufacturing needs include:

- Localized representation

- Saves time & money

- Enhanced security & safety

- Seasoned & experienced

- Contacts across the globe

- Reliable & trustworthy

Contact Sun Fast for Offshore Steel Cold Heading Services Today

Sun Fast’s offshore cold heading specialists use only high-quality materials in their production processes. Our expert cold headed manufacturing partners utilize state-of-the-art equipment to meet the cold head fabrication needs of our customers with exceptional precision and part-to-part repeatability. We can deliver finished products in quick turnaround times to meet the needs of your schedule, in quantities to meet your demands, and at prices to fit your budget.

Contact us for your cold heading needs, or submit a project today.

Offshore Cold Heading Industrial Applications

Sun Fast’s cold heading partners can produce parts in a wide variety of sizes. This including those with numerous metal makeups, and those with custom configurations to meet the needs of almost any application. Due to these options, we serve clients in a broad spectrum of industries including:

- Medical & Dental – We provide extremely small cold headed metal parts made from, or plated with, biocompatible materials for dental implants and medical devices.

- Automotive– Sun Fast also provides cold headed forgings for the automotive industry that are made from carbon steel or other high strength materials.

- Electronic Devices – Cold head fabrication is also used to produce solid and bimetal contact rivets for electronic devices.

The unique, “custom” nature of the cold heading process allows for almost unlimited possibilities in part design.

Why Choose Offshore Cold Heading Fabrication?

There is a substantial investment cost associated with purchasing and housing the machines that produce cold headed steel parts and components. In addition, professional employee labor costs to operate the machines that produce cold-headed products can be extremely high. Other considerations include the additional square footage housing costs associated with storing the machines, as well as machine upkeep and repairs.

Off Shore Cold Heading Fabrication Benefits

The cold heading process produces parts and components that are completely customized to your exact specification requirements. This can include customized head shapes, multiple upset configurations, and substitutions for multi-part assemblies. Some of the advantages of working with a trusted offshore sourcing agent like Sun Fast for your offshoring cold heading manufacturing needs include:

- Localized representation

- Saves time & money

- Enhanced security & safety

- Seasoned & experienced

- Contacts across the globe

- Reliable & trustworthy

Contact Sun Fast for Offshore Steel Cold Heading Services Today

Sun Fast’s offshore cold heading specialists use only high-quality materials in their production processes. Our expert cold headed manufacturing partners utilize state-of-the-art equipment to meet the cold head fabrication needs of our customers with exceptional precision and part-to-part repeatability. We can deliver finished products in quick turnaround times to meet the needs of your schedule, in quantities to meet your demands, and at prices to fit your budget.

Contact us for your cold heading needs, or submit a project today.